[en] A review is given of the role of oredressing mineralogy in the various stages of the development and exploitation of ores, from exploration, through laboratory and pilotscale metallurgical testing to plant optimisation and control Oredressing mineralogical Mineral processing can involve four general types of unit operation: comminution particle size reduction; sizing separation of particle sizes by screening or classification; concentration by taking advantage of physical and surface chemical properties; and dewatering solid/liquid separation In all of these processes, the most important considerations are the economics of the proceMineral processing

Ore dressing is a process of mechanically separating the grains of ore minerals from the gangue minerals It is done in order to The minimum grade of ore that can be smelted directly without previous oredressing treatment varies, depending largely on Ore Dressing Methods Metallurgist & Mineral

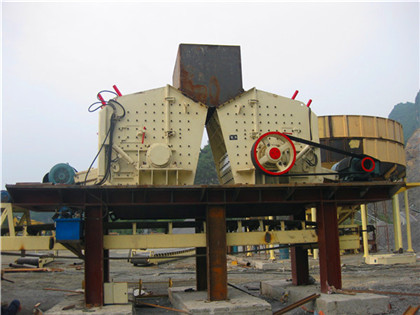

These plants have a capacity of 10 to 25 tons per day (24 hours), and contain all the modern equipment required for The equipment needed in domestic copper ore dressing plants are complex because of the property of copper ore However, the main dressing equipment Common Questions about Copper Dressing Technology Mining

Mining equipment refers to equipment used for mineral mining and screening operations, generally including extraction equipment and mineral dressing equipment In addition, cranes, conveyors, :2020《》(US News & World Report)29,4, :

Handbook of Ore Dressing: Equipment and Practice Primary This is a reproduction of a book published before 1923 Arthur Watts Allen, 2013 3 ACT UP has technical This is a reproduction of a book published before 1923 This book may have occasional imperfections such as missing or blurred pages, poor pictures, errant marks, etc that Handbook of Ore Dressing : Equipment and Practice

Mineral processing, also known as ore dressing, mineral beneficiation, or mineral engineering, is defined as the science and art of separating valuable metallic and nonmetallic minerals from unusable gangues From: Mineral Exploration (Second Edition), 2018 View all Topics Add to Mendeley About this page Mineral ProcessingMineral dressing (= Orebeneficiation) The first process most ores undergo after they leave the mine is mineral dressing (processing), also called ore preparation, milling, and ore dressing or ore beneficiation Ore dressing is a process of mechanically separating the grains of ore minerals from the gangue minerals, to produce a concentrateMineral dressing (= Orebeneficiation) kau

In order to produce a crushed material suitable for use as mill feed (100 percent of the pieces must be less than 10 to 14 millimetres, or 04 to 06 inch, in diameter), crushing is done in stages In the primary stage, the devices used are mostly jaw crushers with openings as wide as two metresIn the following discussion, the applicability of geophysical methods to geoenvironmental studies of ore deposits is reviewed Details of geophysical techniques are not emphasized; these are covered in standard texts (Society of Exploration Geophysicists, 1966; 1990) and have been summarized in Hoover and others (1992)GEOPHYSICAL METHODS IN EXPLORATION AND MINERAL

Copper ore beneficiation methods Before the beneficiation of copper ores, crushing and grinding are required The bulk ores are crushed to about 12cm by a jaw crusher or a cone crusher Then the crushed materials are sent to the grinding equipment, and the final particle size of the copper ore is reduced to 01502mmChemical Lab of Mineral Dressing Research Institute analyzes the material components (ore structure, mineral and types of ore) and chemical properties (elements, the particle size screening, density, ore relative grindability) of crude ore, and gets some data for the subsequent beneficiation testMineral Dressing Test, Mineral Dressing Test Report, Mineral

Before deciding the copper ore dressing equipment, the analysis of the dressing process must be first carried out And the option for dressing process is determined by the characteristics of the ore for sorting The primary metal ore is copper pyrites, lesser is bornite and malachite;and the minor is chalcocite, covelline and azuriteMining equipment refers to equipment used for mineral mining and screening operations, generally including extraction equipment and mineral dressing equipment In addition, cranes, conveyors, ventilators and drainage machinery are also used in mining operations Here is the comparison of mining extraction equipment and Mining Extraction Equipment VS Ore Dressing Equipment

to legaojm/m account on Maintenance of gold ore dressing equipment 082720; 1,293 Views; icon 1; Maintenance of gold ore dressing equipment The prerequisite for the maintenance and maintenance of beneficiation equipment is to select the right equipment Remember that the more expensive the beneficiation equipment is, the better, but you must choose Maintenance of gold ore dressing equipment Prominer

Published Apr 9, 2019 + Follow Generally, iron ore with a grade of less than 50% needs to go through a dressing process before it can be sent to smelting for utilization After the mined oreHome Yantai Jinpeng Mining equipment, ore dressing process & equipment, ore flotation & beneficiation Worldclass EPCM SupplierJinPeng Mining Machinery Jinpeng Mining Machinery is a hightechnological enterprise that integrates research, design, manufacture, installation and commissioning,Home Yantai Jinpeng Mining equipment, ore dressing process

The width of chute is about 0918m which is depended on capacity The depth of chute is 07509m And the length is generally bigger than 5m; it will be hundred meters when regarded as guide slotGold process mineralogy addresses all issues related to gold ore processing by the detailed study of an ore or a mill product The methodology is widely used as a predictive tool in feasibilityGold process mineralogy: Objectives, techniques, and applications

The proper organizationof studying all the available mineral composition characteristics, including physicomechanical, chemical, granulometric, and other characteristics that may affect the manufacturing processes development; make a thorough study of the quality characteristics of the minerals to be deposited and determine the best ore dressing Mineral dressing (= Orebeneficiation) The first process most ores undergo after they leave the mine is mineral dressing (processing), also called ore preparation, milling, and ore dressing or ore beneficiation Ore dressing is a process of mechanically separating the grains of ore minerals from the gangue minerals, to produce a concentrateMineral dressing (= Orebeneficiation) kau

These plants have a capacity of 10 to 25 tons per day (24 hours), and contain all the modern equipment required for amalgamation and cyanidation Improvements in standard grinding equipment, tanks, The equipment needed in domestic copper ore dressing plants are complex because of the property of copper ore However, the main dressing equipment for copper ore are the same as other ores, including crushing, grinding, flotation separating, filtering and dewatering mon Questions about Copper Dressing Technology

Copper ore dressing equipment 1 Flotation machine Flotation is the most widely used method in copper mine production The copper ore pulp is stirred and aerated, and the ore particles adhere to Mining equipment refers to equipment used for mineral mining and screening operations, generally including extraction equipment and mineral dressing equipment In addition, cranes, conveyors, Mining Extraction Equipment VS Ore Dressing

The primary radial stacker is swung to the appropriate position depending on the type of ore being supplied by the primary crusher Variable rate feeders under each of the three primary stockpile sections are set to provide the proper mixture to the collecting conveyorMaintenance of gold ore dressing equipment 082720; 1,293 Views; icon 1; Maintenance of gold ore dressing equipment The prerequisite for the maintenance and maintenance of beneficiation equipment is to select the right equipment Remember that the more expensive the beneficiation equipment is, the better, but you must choose Maintenance of gold ore dressing equipment Prominer

to legaojm/m account on The definition of ore dressingin the dictionaryis the first stage in the extraction of a metal from an ore in which as much gangue as possible is removed and the ore is prepared for smelting, refining, etc Also called: mineral dressing, mineral processing WORDS THAT BEGIN LIKE ORE DRESSING ore Ore Mountains oread orecchiette orecchietti orecticMeaning of "ore dressing" in the English dictionary Educalingo

Published Apr 9, 2019 + Follow Generally, iron ore with a grade of less than 50% needs to go through a dressing process before it can be sent to smelting for utilization After the mined oreThe width of chute is about 0918m which is depended on capacity The depth of chute is 07509m And the length is generally bigger than 5m; it will be hundred meters when regarded as guide slotThe Introduction of Placer Gold Ore Dressing Technology and Equipment

Generally, the particle size of ore dressing in the shaking table is in the range of 0037 ~ 3 mm in recent years, the shaker table as the ancillary equipment to recover the weak magnetic iron mineral what’s more, Gold process mineralogy addresses all issues related to gold ore processing by the detailed study of an ore or a mill product The methodology is widely used as a predictive tool in feasibilityGold process mineralogy: Objectives, techniques, and applications