The CuTa (CopperTantalum) system SpringerLink Alloy Phase Diagram Evaluations Published: December 1989 The CuTa (CopperTantalum) system P R Subramanian & Therefore, a mechanical separation process can separate and collect the tantalum capacitors from the treated WPCBs For both processes molten salt or metal Tantalum Capacitor Separation from Waste Printed Circuit

The final stage of copper CMP requires the simultaneous polishing of copper and the barrier metal, where the metals are prone to galvanic corrosion due to exposure to slurry To collect the sintered tantalum electrodes, approximately 6 g of tantalum capacitor scraps (equal to 20 pieces of capacitors) were placed on a ceramic plate and Development of a recycling process for tantalum from

To investigate the separation of the inner and outer liners during the formation of tandem EFPs, the doublelayer liners with the same thickness of 15 mm The CuTa (CopperTantalum) system SpringerLink Alloy Phase Diagram Evaluations Published: December 1989 The CuTa (CopperTantalum) system P R Subramanian & D E Laughlin Bulletin of Alloy Phase Diagrams 10,652–655 ( 1989) Cite this article 639 Accesses 58 Citations Metrics Download to read the full article text Cited ReferencesThe CuTa (CopperTantalum) system SpringerLink

The copper–tantalum sample was placed on a stack of two copper foils separated by an insulating material A thin aluminum foil was used to make electrical contact between the Ta portion of the sample and one of the circular copper foils The Cu part of the sample was connected to the other copper foil at the bottom through the window in theTherefore, a mechanical separation process can separate and collect the tantalum capacitors from the treated WPCBs For both processes molten salt or metal the epoxy encapsulation of the tantalum capacitors did not disintegrate into a powder nor disengage from the tantalumcontaining coreTantalum Capacitor Separation from Waste Printed Circuit

To collect the sintered tantalum electrodes, approximately 6 g of tantalum capacitor scraps (equal to 20 pieces of capacitors) were placed on a ceramic plate and oxidized in the air at a constant temperature between 773 and 1273 K for a fixed period of time (05–3 h)The iron and nickel terminals were able to be removed by magnetic GEOMETRY OF DAMAGE IN SHOCK LOADED COPPER AND TANTALUM Full Record Related Research Abstract Cavities of coalesced voids have been found in recovered samples of Tantalum in highexplosivedriven experiments The boundaries of these cavities are imprinted with details of the coalescence and void GEOMETRY OF DAMAGE IN SHOCK LOADED COPPER AND TANTALUM

Recently, copper tantalum sulfide (CuTaS 3) has been proposed as a potential light absorber for photovoltaics The synthesis conditions and growth mechanism of ternary systems control the final composition and crystal structure (Cu : Ta) ratio of 1 : 1 Separate syntheses having Curich (Cu : Ta = 3 : 1) and Tarich (Cu : Ta = 1 : 3MUNICH, Germany — The Munich Research Labs of European chipmaker Infineon Technologies AG have demonstrated that tantalum nitride capping layers for integrated circuit copper interconnect can be made and work at thickness below two nanometers, the company said Tuesday (May 27, 2003) The results of fabrication Infineon shows tantalumwithcopper has a long future

The industrial treatment of DXN concentrates consists of the digestion of the concentrate using a mixture of sulphuric and hydrofluoric acid at temperatures between 250 and 300 °C to form niobiumCopperTantalum Metal Matrix Composites Consolidated from Powder Blends by Severe Plastic Deformation Full Record References (37) Related Research Abstract We investigated the effectiveness of severe plastic deformation by equal channel angular extrusion (ECAE) for consolidation of metal powders into metal matrix CopperTantalum Metal Matrix Composites Consolidated from Powder Blends

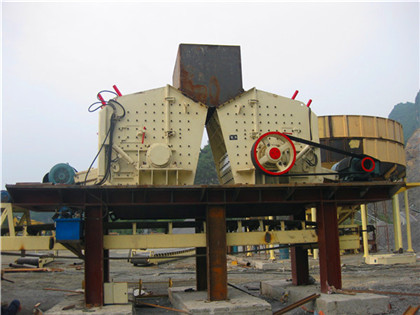

High Tension Mining Electrostatic Separator Electric Two Rolls Four Rollers for Zircon Sand Mineral Gold Tin Rutile Monazite Ore Iron Copper Tantalum Separation Our factory produce full sets mining equipments for separating zircon sand, rutile ore, monazite, ilmenite, magnetic iron ore, tin ore and so on For many years, the separation of tantalum from niobium involved the fractional crystallization of potassium heptafluorotantalate away from potassium oxypentafluoroniobate monohydrate FluoridesA Review of NiobiumTantalum Separation in

Permeation through membranes, especially those made of palladium alloys such as Pd–Ag, is also mentioned and sometimes proposed as a potential process for the separation of hydrogen isotopes as required in future fusion plants [1], [2]Two primary techniques can be distinguished for this process: large total pressure differences (A) or The tantalum must be evenly distributed longitudinally throughout the copper so that as the copper and tantalum melt individually, a homogeneous melt is formed Preferably, the tantalum is firmly afixed to the copper billet so that as the electrode melts, a piece of unmelted tantalum could not separate from the electrode and fall into the meltUSA Coppertantalum alloy Google Patents

Firstprinciples study of thermodynamical and mechanical stabilities of thin copper film on tantalum Adham Hashibon, Christian Elsässer, Yuri Mishin, and Peter Gumbsch Phys Rev B 76, Published 27 December 2007 More With respect to interface separation, the monolayer is found to be bound more strongly to the Ta The CuTa (CopperTantalum) system SpringerLink Alloy Phase Diagram Evaluations Published: December 1989 The CuTa (CopperTantalum) system P R Subramanian & D E Laughlin Bulletin of Alloy Phase Diagrams 10,652–655 ( 1989) Cite this article 639 Accesses 58 Citations Metrics Download to read the full article text Cited ReferencesThe CuTa (CopperTantalum) system SpringerLink

The copper–tantalum sample was placed on a stack of two copper foils separated by an insulating material A thin aluminum foil was used to make electrical contact between the Ta portion of the sample and one of the circular copper foils The Cu part of the sample was connected to the other copper foil at the bottom through the window in theCopper and tantalum atomic absorption standard solutions were purchased from Aldrich Chemical Company More specifically, the collected slurry was first centrifuged to separate the abrasive particles The particles were washed with DI water three times and then 1 N HNO 3 to dissolve Cu or Ta that is bonded to the particle Interaction between abrasive particles and films during

The recycling of metals such as copper and steel from waste printed circuit boards in molten salts was shown by earlier experiments 14 This paper extends those experiments to the recycling of SMD tantalum capacitors Therefore, a mechanical separation process can separate and collect the tantalum capacitors from the treated The copper terminals were removed by sieving, and the obtained tantalum oxide, containing copper fragments and other impurities, was treated in nitric acid to remove the impurities The powder obtained after rinsing with water was calcinated in the air at 1273 K for an hour to remove water and carbon compoundsDevelopment of a recycling process for tantalum from capacitor

Recently, copper tantalum sulfide (CuTaS 3) has been proposed as a potential light absorber for photovoltaics The synthesis conditions and growth mechanism of ternary systems control the final composition and crystal structure (Cu : Ta) ratio of 1 : 1 Separate syntheses having Curich (Cu : Ta = 3 : 1) and Tarich (Cu : Ta = 1 : 3CopperTantalum Metal Matrix Composites Consolidated from Powder Blends by Severe Plastic Deformation Full Record References (37) Related Research Abstract We investigated the effectiveness of severe plastic deformation by equal channel angular extrusion (ECAE) for consolidation of metal powders into metal matrix CopperTantalum Metal Matrix Composites Consolidated from Powder Blends

Tantalum is an extremely rare precious metal, which is regarded as an emerging strategic metal It is widely used in many fields, especially in the fields of energy, national defense, high and new science and technology, and plays an irreplaceable role With the increasing application scope, the amount of Tantalum increases greatly For many years, the separation of tantalum from niobium involved the fractional crystallization of potassium heptafluorotantalate away from potassium oxypentafluoroniobate monohydrate FluoridesA Review of NiobiumTantalum Separation in

Separation of high accuracy, can make the 120 mesh mineral to 2 mm High degree of automation, to achieve the feeding, heating, speed adjustment, highpressure discharge, with high security Our factory produce two rollers and The tantalumsintered bodies were separated from molded resins by heat treatment at 723–773 K in air atmosphere and screening of 05 mm Silica was removed and 70% of tantalum grade was obtainedRecycling of Tantalum from Waste Electrical and ResearchGate

Firstprinciples study of thermodynamical and mechanical stabilities of thin copper film on tantalum Adham Hashibon, Christian Elsässer, Yuri Mishin, and Peter Gumbsch Phys Rev B 76, Published 27 December 2007 More With respect to interface separation, the monolayer is found to be bound more strongly to the Ta Preferably, the tantalum is firmly afixed to the copper billet so that as the electrode melts, a piece of unmelted tantalum could not separate from the electrode and fall into the melt TheUSA Coppertantalum alloy Google Patents

MUNICH, Germany — The Munich Research Labs of European chipmaker Infineon Technologies AG have demonstrated that tantalum nitride capping layers for integrated circuit copper interconnect can be made and work at thickness below two nanometers, the company said Tuesday (May 27, 2003) The results of fabrication