In this paper, vibration characteristics of a Vertical Roller Mill (VRM) are studied by using physical parameters of an operating VRM The mathematical model is In this study the dynamic behaviour and vibration parameters of Injection Moulding Machine Base Structure was performed by analysing the structure numerically (PDF) Design and Vibration Analysis of Injection

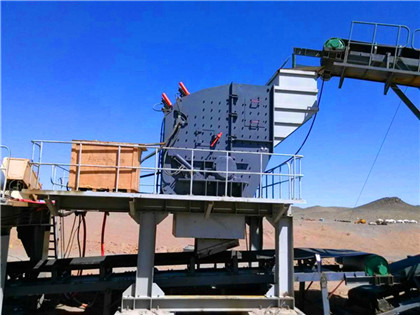

Bian Huamei et al [7] observed that CNC vertical machine vibration characteristics and achieved vibration signal and source of spindle speed, results tool Vertical roller mills Overview Products What we offer Customer stories Vertical roller mills offer supreme grinding with high energyefficiency Whether grinding raw coal, clinker, cement and/or slag, we have a VRM Vertical Roller Mills

Keywords: vertical roller mill, model predictive control, proportional integral and derivative control, artificial neural networks, fuzzy logic 1 INTRODUCTION The VRM is a type of The utility model provides a water injection device of a vertical mill, which can be used for well stabilizing a material layer, reducing vibration of the mill, CNU Water injection device of vertical mill

Higher coal flows will result in lower fineness The second, which is rarely needed, is to install small irregularities in the grinding ring that “bump” the roll and keep it turning This can be accomplished with either vertical North American Headquarters Shibaura Machine Company, America; 755 Greenleaf Avenue Elk Grove Village, IL 60007; United States (888) 5931616; smainfo@shibaura Vertical Boring & Turning Mill Shibaura Machine

The main causes of vertical mill vibration are: The roller lining and the grinding disc are not installed firmly; The horizontal error between the reducer base and 1 Introduction The CNC vertical milling machine is a very important machine tool in the equipment manufacturing industry, which can process parts with complex shapes in batches with high machining accuracy and high efficiency [1], [2], [3]With the increasing requirements for product quality and high speed machining, it is urgent to The vibration analysis of the CNC vertical milling machine

Abstract In this paper, vibration characteristics of a Vertical Roller Mill (VRM) are studied by using physical parameters of an operating VRM The mathematical model is derived and simulated forIn this study the dynamic behaviour and vibration parameters of Injection Moulding Machine Base Structure was performed by analysing the structure numerically as well as experimentally Modal(PDF) Design and Vibration Analysis of Injection ResearchGate

The vibration phenomenon of the rolling mill always exists during working The vibration of the rolling mill not only reduces the quality of the products, but also damages the equipment in severe cases and even leads to huge economic losses [1, 2]In order to avoid the vibration of the rolling mill, a lot of research work has been Texturing is an engineering technology that can be used to enable surface functionalization in the plastics injection molding industry A texture is defined as the geometrical modification of the topography by addition of surface features that are characterized by a smaller scale than the overall surface dimensions Texturing is added Texturing Technologies for Plastics Injection Molding: A Review

The main causes of vertical mill vibration are: The roller lining and the grinding disc are not installed firmly; The horizontal error between the reducer base and the foundation exceeds the specified range; The stopper ring is not installed properly; The stretching rod has deviations after longterm operation, resulting in uneven stressOverall vibration levels can indicate a change in mill condition, and vibration analysis can identify deteriorating components In summary, low vibration levels and machine reliability can be maintained by: 1 Optimize machine operation with vibration feedback to the control system and operatorsCement Industry Raw Mill Vibration Monitoring AMP

The causes of the vertical grinding vibration and the treatment measures are as follows: 1) The foreign matter inside the mill causes vibration Metal foreign objects from inside and outside the mill, such as wind guide vanes, and tools left over after repair If it is a small metal, it can lift the grinding roller and reduce the air suctionA vibration mill is a size reduction equipment that applies the process of continuous impaction in carrying out its size reduction function The grinding container is made up of a tube that is held in a frame that is supported by means of springs which is filled to approximately 80% total volume with porcelain or stainless steel ballsVibration Mill Qingdao EPIC Powder Machinery

As Figures 6(a)–6(c) show, the dynamic bifurcation characteristics of horizontal, vertical, and torsional vibrations are the same, which also reflects the coupling When e 1 < 04 mm, the system 23 Nonlinear Coupled Vibration Model of Hot Rolling Mill Rolls According to the structure diagram of the fourhigh hot rolling mill shown in Figure 1, we consider the structural constraints on the roll and the effect of Coupled Vibration Behavior of Hot Rolling Mill Rolls

The rolling mill vibration not only seriously causes the strip thickness heterogeneity, but also damages the rolling mill equipment and its electrical components Existing vibration suppression methods are passive and mainly tune mechanical, hydraulic, electrical and rolling process parameters A new active vibration suppression method 2019 vertical mill inspection and maintenance 10 01 Wang Zhanguang ( Jiaozuo strong cement) Vertical mill as cement enterprise host equipment, operation quality directly affect the enterprise benefit, the inspection maintenance is very important, in this paper, in combination with production practice about the region and the The inspection and maintenance of vertical mill WXING Bearing

f VIBRATIONS IN ROLLER MILL MONITORED BY MEANS OF A VIBROMETER PLACED ON THE GEAR BOX FOUNDATION VIBRATION ALARMS ACOUSTIC ALARM AFTER 5 SEC AT MORE THAN 3 mm/s MILL STOPPAGE AFTER 5 SEC AT MORE THAN 4 mm/s INSTANTANEOUS STOPPAGE AT MORE THAN 8 mm/s ff• IF POWER 1 Introduction The CNC vertical milling machine is a very important machine tool in the equipment manufacturing industry, which can process parts with complex shapes in batches with high machining accuracy and high efficiency [1], [2], [3]With the increasing requirements for product quality and high speed machining, it is urgent to The vibration analysis of the CNC vertical milling machine

Abstract In this paper, vibration characteristics of a Vertical Roller Mill (VRM) are studied by using physical parameters of an operating VRM The mathematical model is derived and simulated forThe rolling mill with hydraulic system is widely used in the production of strip steel For the problem of vertical vibration of the rolling mill, the effects of different equivalent damping coefficient, leakage Processes Free FullText Research on the Vertical

This paper reports on the effects of spindle attributed forced vibrations on machinability characteristics of vertical milling process The effects of three levels of spindle attributed forced vibrations along with feed rate and axial depth of cut are evaluated on surface roughness, dimensional accuracy, and tool wear under constant conditions of In this study the dynamic behaviour and vibration parameters of Injection Moulding Machine Base Structure was performed by analysing the structure numerically as well as experimentally Modal(PDF) Design and Vibration Analysis of Injection ResearchGate

The vibration phenomenon of the rolling mill always exists during working The vibration of the rolling mill not only reduces the quality of the products, but also damages the equipment in severe cases and even leads to huge economic losses [1, 2]In order to avoid the vibration of the rolling mill, a lot of research work has been The vibration of the vertical mill is related to many factors such as transmission, material layer, foreign matter, roll surface, grinding disc, particle size, pressure and so on 1 Vibration caused by Characteristics and Cause Analysis of Vibration in

Texturing is an engineering technology that can be used to enable surface functionalization in the plastics injection molding industry A texture is defined as the geometrical modification of the topography by addition of surface features that are characterized by a smaller scale than the overall surface dimensions Texturing is added In addition, the abnormal vibration caused by the loosening and falling off of the screws and bolts can easily cause the unstable operation of the equipment, which brings a great safety hazard to the milling production Therefore, when using a vertical roller mill to process and grind materials, it is necessary to analyze the causes of theWhat Are The Reasons For The Abnormal Vibration Of Large Vertical

Geometry of the verticalhorizontaltorsional vibration model As shown in Figure 4, M1, M2, and M3are the equivalent mass of the upper part of mill stand, backup roll, and work roll J1and J2are the 23 Nonlinear Coupled Vibration Model of Hot Rolling Mill Rolls According to the structure diagram of the fourhigh hot rolling mill shown in Figure 1, we consider the structural constraints on the roll and the effect of Coupled Vibration Behavior of Hot Rolling Mill Rolls

The causes of the vertical grinding vibration and the treatment measures are as follows: 1) The foreign matter inside the mill causes vibration Metal foreign objects from inside and outside the mill, such as wind guide vanes, and tools left over after repair If it is a small metal, it can lift the grinding roller and reduce the air suctionThe factors that cause vibration are: the basis of the mill, the grinding pressure, the thickness of the layer, the air volume and the air temperature, the accumulator pressure, the wear of the roller surface or the grinding disc, and the likeimportant operation tips for cement vertical mill

2019 vertical mill inspection and maintenance 10 01 Wang Zhanguang ( Jiaozuo strong cement) Vertical mill as cement enterprise host equipment, operation quality directly affect the enterprise benefit, the inspection maintenance is very important, in this paper, in combination with production practice about the region and the