The article presents the results of laboratoryscale research on the determination of the impact of ball mill parameters and This study evaluated the impact of replacing steel cylpebs with ceramic balls on the grinding effect, circulating load, classification effect, and the change of the The first attempt of applying ceramic balls in industrial tumbling

Designed already at the end of the twentieth century, the investigated drive systems of the ball mills installed in the copper ore We took on the challenge and completed the changeout of 7500 and 8500 HP SAG grinding ball mill motors with Coldelco Andina in two months Home Insights Case studies Mining and metals Codelco Andina changes the main motors of its ball mills

Sorrentino19 In particular they classify the ball mills in two groups depending on their operation mode: direct and indirect milling In the rst case rollers or mechanical sha s Figure 14 shows diagrams for grade analysis of molybdenum, copper, and iron in two modes of millon and milloff for closedcircuit ball mill According to the A process mineralogy approach to study the efficiency of

Capacity: 16386t/h Applicable materials: Copper ore, iron ore, gold ore, quartz stone, etc Get Price Now Copper ball mill, sometimes called copper ore ball mill or copper mine ball mill, is indispensable grinding As production capacity at Cobré Panama continues to be developed to ultimately process 100 Mtpa of ore, Lycopodium is providing engineering, design, procurement and construction support services for the mine’s Case Study Cobré Panama Project Lycopodium

This case study describes bearing damage detected through online measurements taken from a ball mill at the flotation plant of Asarel Medet AD in Bulgaria Asarel Medet AD is among the largest To further enable this, a smaller size laboratorybased AG/SAG mill by 30 cm diameter to 15 cm length has been developed along with additional functionality, following the Magotteaux ball mill(PDF) Mixed media grinding A refractory gold case

The case study mills have all the because the mineral goes faster to the mill discharge, leaving a greater part of the grinding task to the secondary ball mills Simkus, R, Dance, A, 1998 Tracking hardness and size: measuring and monitoring ROM ore properties at highland valley copper In: Mine to Mill98, Brisbane, Australia, 1998Comparative grinding tests of twostage closed HPGR with 7 mm and 1 mm screens and a final mill grind, and twostage closed HPGR with a 7 mm screen and an air classifier cutting for finalCase Study of Dry HPGR Grinding and Classification

In this study, a method for assessing load state in ball mill based on instrumented grinding media was developed The instrumented grinding media can detect the acceleration of impact in the running mill Clear difference was observed in the waveform under different load states The grinding efficiency index and the Designed already at the end of the twentieth century, the investigated drive systems of the ball mills installed in the copper ore processing plant were provided with SAS motors ( Figure 2 ) The motors Energy Efficiency Analysis of Copper Ore Ball Mill

The paper presents a study on the effectiveness of the grinding process in an electromagnetic mill devoted to ultrafine grinding, and the influence of processing parameters on the mill’s performance The research was focused on the optimization of the duration of the grinding process and selection of the grinding media type in order We took on the challenge and completed the changeout of 7500 and 8500 HP SAG grinding ball mill motors with Coldelco Andina in two months Home Insights Case studies Mining and metals Codelco Andina changes the main motors of its ball

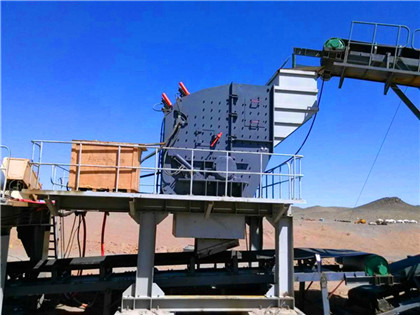

Sorrentino19 In particular they classify the ball mills in two groups depending on their operation mode: direct and indirect milling In the rst case rollers or mechanical sha s directly act on the particles and transfer the kinetic energy In the second case the kinetic energy is rstly transferred to the mill body and then to the grinding mediumPERI™ AutoCharge Mill Grinding Ball Charging System Copper: Technology: SemiMobile Crushing Plant: Application: InPit Crushing and Conveying: Study type: Case study: Country: Kazakhstan: The current truckandshovel operation currently consumes more than 50 million litres of diesel a year By adopting a semimobile crushing plantHow semimobile crushing cuts costs and emissions at a large copper

seconds by ball mill During this period of time, more than50% of material left the fraction It means the mentioned time is more than enough In this respect 15, 30, 45, and 60 seconds were selected as grinding times After this step, a pulp with 60% solidof each fraction (equivalent to feed concentration of Miduk copper ball mills) was prepared to legaojm/m account on m/ mineral grinding ball mill plant and its specifiion inmd at

The ball mill grinding efficiency was poor and could be indicated by the fraction < 125 µm of only 59 % or xP, 80 : >400 µm in the mill discharge This was deemed due to poor hydrocycloneThe simulations indicated that the novel comminution circuit had the potential to remove two MP1000 pebble crushers and one 10MW ball mill from the existing 2000 t/h grinding circuit A 5 kWh/t energy reduction by adopting the novel comminution circuit in a goldcopper operation may be realizedA potential application of high voltage pulse technology in a gold

According to the results, grinding by opencircuit ball mill has caused the particles size to decrease from 900% smaller than 450 microns to about 990% smaller the 450 microns GrindingIn the second case the kinetic energy is firstly transferred to the mill body and then to the grinding medium These ball mills are the most widely used in the field of cellulose and they can be further divided into three groups: tumbler ball mills, vibratory mills and planetary mills A tumbler mill consists of a cylinder partially filledBall milling: a green technology for the preparation and

This ball mill modelling technique is illustrated using a case study on the design of a ball milling circuit for a particular grinding requirement and another case study on modelling the performance of an industrial ball milling circuit The Bougainville Copper Limited Concentrator MC Fuerstenau (Ed),The case study mills have all the same discharge system, resulting in a lower variation in the effect of the slurry pooling on power ( Moys et al, 1996 ) As an important independent variable, the feed size distribution (not just the F80) was chosen as a model variable, represented by an operation relevant size fractionModelling SAG milling power and specific energy ScienceDirect

Comparative grinding tests of twostage closed HPGR with 7 mm and 1 mm screens and a final mill grind, and twostage closed HPGR with a 7 mm screen and an air classifier cutting for finalDesigned already at the end of the twentieth century, the investigated drive systems of the ball mills installed in the copper ore processing plant were provided with SAS motors ( Figure 2 ) The motors Energy Efficiency Analysis of Copper Ore Ball Mill

The paper presents a study on the effectiveness of the grinding process in an electromagnetic mill devoted to ultrafine grinding, and the influence of processing parameters on the mill’s performance The research was focused on the optimization of the duration of the grinding process and selection of the grinding media type in order Sorrentino19 In particular they classify the ball mills in two groups depending on their operation mode: direct and indirect milling In the rst case rollers or mechanical sha s directly act on the particles and transfer the kinetic energy In the second case the kinetic energy is rstly transferred to the mill body and then to the grinding mediumBall milling: a green technology for the preparation and

PERI™ AutoCharge Mill Grinding Ball Charging System Copper: Technology: SemiMobile Crushing Plant: Application: InPit Crushing and Conveying: Study type: Case study: Country: Kazakhstan: The current truckandshovel operation currently consumes more than 50 million litres of diesel a year By adopting a semimobile crushing plantCase Study RAW MILL GRINDING ROLLER 13 INDUSTRIAL CASE STUDY: THE CEMENT INDUSTRY PREPARED BY Condition Monitoring Cell Shree Cement Ras SHREECEMENTLTD Case Study RAW MILL GRINDING ROLLER 13

The ball mill grinding efficiency was poor and could be indicated by the fraction < 125 µm of only 59 % or xP, 80 : >400 µm in the mill discharge This was deemed due to poor hydrocycloneWe took on the challenge and completed the changeout of 7500 and 8500 HP SAG grinding ball mill motors with Coldelco Andina in two months Home Insights Case studies Mining and metals Codelco Andina changes the main motors of its ball

seconds by ball mill During this period of time, more than50% of material left the fraction It means the mentioned time is more than enough In this respect 15, 30, 45, and 60 seconds were selected as grinding times After this step, a pulp with 60% solidof each fraction (equivalent to feed concentration of Miduk copper ball mills) was prepared to legaojm/m account on m/ mineral grinding ball mill plant and its specifiion inmd at

The simulations indicated that the novel comminution circuit had the potential to remove two MP1000 pebble crushers and one 10MW ball mill from the existing 2000 t/h grinding circuit A 5 kWh/t energy reduction by adopting the novel comminution circuit in a goldcopper operation may be realizedThe objective of the present work is the comparison of two common milling methods for the production of complex metallic alloy nanoparticles γAl 12 Mg 17 nanoparticles were fabricated using both a planetary ball mill and a SPEX mill The produced nanoparticles have been compared on the basis of the phase and microstructural characterisations by Comparative study of SPEX and planetary milling methods for the