Ball milling is a mechanical technique that is broadly used to grind powders into fine particles [134–141] The reactants are generally broken apart using solvent molecules in Ball milling is a simple, fast, costeffective green technology with enormous potential One of the most interesting applications of this technology in the field of cellulose is the preparation and the chemical modification of Ball milling: a green technology for the preparation and

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell A ball mill consists of a hollow cylindrical shell rotating about its axis The axiFurthermore, ball milling technique coupled with chemical and physicochemical pretreatments has been shown to facilitate lignin removal, reduce Ball milling as an important pretreatment technique in

As the name suggests, the ball milling method consists of balls and a mill chamber Therefore over all a ball mill contains a stainless steel container and many small iron, Furthermore, ball milling technique coupled with chemical and physicochemical pretreatments has been shown to facilitate lignin removal, reduce Ball milling as an important pretreatment technique in

Besides materials synthesis, highenergy ball milling is a way of modifying the conditions in which chemical reactions usually take place either by changing the reactivity of asmilled solids (mechanical activation — In mechanochemical synthesis, the type of ball mill (eg, zirconium dioxide), nature of the milling material [ 32 ], and milling speed and time [ 33] are crucial variables An Efficiency of Mechanochemical Ball Milling Technique in the

The ball milling technique has been widely used to synthesize TiO 2 nanomaterials via top down approach Y Chen et al [55, 56] have studied the ball Ball milling is a simple, fast, costeffective green technology with enormous potential One of the most interesting applications of this technology in the field of cellulose is the preparation and the chemical modification of cellulose nanocrystals and nanofibersBall milling: a green technology for the preparation and

this green, sustainable technique to facilitate the identi cation of areas of future development The ball mill Ball milling is a mechanical technique widely used to grind powders into ne particles and blend materials18 Being an environmentallyfriendly, costeffective technique, it has found wide application in industry all over the worldFurthermore, ball milling technique coupled with chemical and physicochemical pretreatments has been shown to facilitate lignin removal, reduce cellulose crystallinity, and increase the specific surface area which ultimately improves the digestibility of lignocellulosic biomass Over the last decade, several reports have been published on Ball milling as an important pretreatment technique in

This powder will be made into nanosize using the ball milling technique A magnet is placed outside the container to provide the pulling force to the material and this magnetic force increases the milling energy when milling container or chamber rotates the metal balls 3 The ball to material mass ratio is normally maintained at 2 ratio1The bivalent Ni (II) and Co (II) complexes of N’benzylidene3hydroxy2naphthohydrazide ligand were synthesized by ball milling as an efficient technique for quantitative solventfree synthesis The isolated solid compounds will be characterized using several spectroscopic techniques The theoretical studies represented in the Full article: Ball milling: a simple and efficient method for

Besides materials synthesis, highenergy ball milling is a way of modifying the conditions in which chemical reactions usually take place either by changing the reactivity of asmilled solids (mechanical activation — Ball milling, being fast and controllable technique, has been performed with different milling media such as NH4 HCO 3, NaCl and sucrose and investigate the effect of different milling media on the DNDs deaggregation followed by its dispersion behavior in different solvents such as ethanol, water and DMSODispersion behavior and the influences of ball milling technique

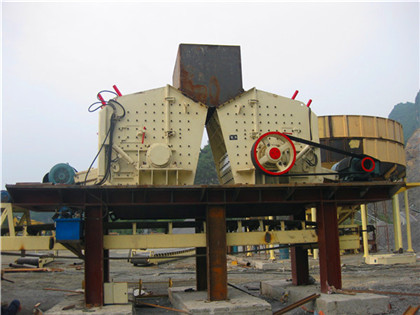

Furthermore, ball milling technique coupled with chemical and physicochemical pretreatments has been shown to facilitate lignin removal, reduce cellulose crystallinity, and increase the specificBall milling technique, using mechanical alloying and mechanical milling approaches were proposed to the word wide in the 8th decade of the last century for preparing a wide spectrum of powder materials and their alloys In fact, ball milling process is not new and dates back to more than 150 years It has been used in size comminutions of ore, Ball Milling an overview ScienceDirect Topics

Both ciprofloxacin (CIP) and sugarcane bagasse have brought enormous pressure on environmental safety Here, an innovative technique combining FeMglayered double oxides and ball milling was presented for the first time to convert bagassewaste into a new biochar adsorbent (BMLDOsBC) for aqueous CIP removalIn this paper, the recent exptl observations reported on development of nanocryst and amorphous structures using ball mill technique are selectively examd and critically reviewed to provide further insight into the key issues related to this solidstate technique The review includes four major partsIntroduction to Pharmaceutical Coamorphous Systems Using a

Biochar has attracted considerable attention in numerous industrial and environmental applications because of its advantageous properties Pyrolysis, a costeffective and ecofriendly engineering technique for improving biochar’s physicochemical and adsorption properties, is important in a variety of environmental applications The In this study, micronanoengineered nitrogenous biochars derived from cow bone meal pyrolyzed at different temperatures and were engineered with the assistance of a ballmilling technique The ballmilled bone biochars were natural composites combined with plant biochars and hydroxyapatite components on the micronanoscale Both the Micronanoengineered nitrogenous bone biochar developed with a ball

Powders of pure elements are mechanically alloyed for 16 h in the planetary mill They show nonuniform composition and consist of α(Cu), α(Ag), Cu 2 Cd, and Cd 3 Ag The crystallite size within powder particles is estimated from Xray and transmission electron microscopy studies in the range of 10 to 30 nmIn this article, we demonstrate a highenergy ball milling technique for largescale synthesis of nitrogen doped carbon nanoparticles, which can be used as an electrocatalyst for oxygen reduction reactions after a Ball milling: a green mechanochemical approach

A ball mill is a type of grinder used to grind and blend bulk material into QDs /nanosize using different sized balls The working principle is simple; impact and attrition size reduction take place as the ball drops from near the top of a rotating hollow cylindrical shellThe bivalent Ni (II) and Co (II) complexes of N’benzylidene3hydroxy2naphthohydrazide ligand were synthesized by ball milling as an efficient technique for quantitative solventfree synthesis The isolated solid compounds will be characterized using several spectroscopic techniques The theoretical studies represented in the Full article: Ball milling: a simple and efficient method for

A novel ball milling technique for room temperature processing of TiO2 nanoparticles employed as the electron transport layer in perovskite solar cells and modules Journal of Materials Chemistry A The ball milling method has the advantages of a short reaction time, large preparation amounts, little or no solvent without heating, and promotion of the industrialization process of MOFs [ 17 ] In 2012, James reviewed the Synthesis of Metal Organic Frameworks by Ball

The milling action was provided by ten steel balls with a density of 7800kg/m3 The number of balls to be employed was carefully optimised, as it was observed that a reduced number of balls is more Furthermore, ball milling technique coupled with chemical and physicochemical pretreatments has been shown to facilitate lignin removal, reduce cellulose crystallinity, and increase the specificBall milling as an important pretreatment technique in lignocellulose

In our research, we use the highenergy ball milling technique to synthesize various nanometer powders with an average particle size down to several nm, including nanosized aFe 2 O 3 based solid solutions Although ball milling equipment is frequently used, many users are still curious about it Therefore, in order to better help users use the ball mill, the specific working principle of the ball mill is introduced as follows: The ball milling process is generally divided into two types, the dry ball milling process, and the wet ball millingWhat is Ball Milling Process? ball mills supplier

Both ciprofloxacin (CIP) and sugarcane bagasse have brought enormous pressure on environmental safety Here, an innovative technique combining FeMglayered double oxides and ball milling was presented for the first time to convert bagassewaste into a new biochar adsorbent (BMLDOsBC) for aqueous CIP removalIn this paper, the recent exptl observations reported on development of nanocryst and amorphous structures using ball mill technique are selectively examd and critically reviewed to provide further insight into the key issues related to this solidstate technique The review includes four major partsIntroduction to Pharmaceutical Coamorphous Systems Using a

In this study, micronanoengineered nitrogenous biochars derived from cow bone meal pyrolyzed at different temperatures and were engineered with the assistance of a ballmilling technique The ballmilled bone biochars were natural composites combined with plant biochars and hydroxyapatite components on the micronanoscale Both the Biochar has attracted considerable attention in numerous industrial and environmental applications because of its advantageous properties Pyrolysis, a costeffective and ecofriendly engineering technique for improving biochar’s physicochemical and adsorption properties, is important in a variety of environmental applications The Effects of Pyrolysis and BallMilling on the Physicochemical and

Powders of pure elements are mechanically alloyed for 16 h in the planetary mill They show nonuniform composition and consist of α(Cu), α(Ag), Cu 2 Cd, and Cd 3 Ag The crystallite size within powder particles is estimated from Xray and transmission electron microscopy studies in the range of 10 to 30 nm