Based on the obtained results by the investigation of the features of magnetite–hematite ores from the Mikhailovskoye deposit, a technological scheme of magnetoflotation beneficiation was proposed, which allows producing iron The technologies applicable to beneficiating iron ore fines include wet and dry gravity and magnetic separation, flotation, and roasting followed by magnetic Beneficiation Strategies for Removal of Silica and Alumina from

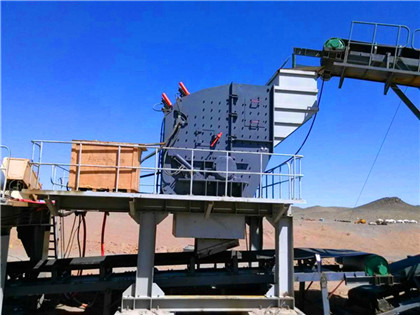

The process flow of the extraction of iron from hematite is as follows: crushing, grinding, extracting (flotation separation, magnetic separation, gravity In this paper, the mineral beneficiation process for hematite is studied, where the technique of screeningroastinggrindingmagnetic separationdewatering is Databased multiplemodel prediction of the production

In Fig 3, the typical beneficiation of the oxide iron ores magnetite and haematite are shown Easiest to beneficiate are haematite ores (bottom part of the picture) In Hematite Processing by Flotation Direct shipping of high grade iron ore, because of depletion or partial depletion of reserves, or high costs of operation has forced operators to use some means of Hematite Processing by Flotation Mineral Processing

Hematite is the world’s most important ore of iron Although magnetite contains a higher percentage of iron and is easier to process, hematite is the leading ore because it is more abundant and present in deposits in The process flow of "stage grinding, coarse subdivision and separation, gravity separation→strong magnetic→anion reverse flotation" is used to separate poor Hematite beneficiation technology,processing of iron mineral,ore

Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments Most are sedimentary, but many have been changed by The hematite is easily separated from the gangue and enters the jigger for gravity beneficiation after crushing and screening After washing, jigging, and spiral HEMATITE BENEFICIATION PROCESS, HEMATITE

Based on the obtained results by the investigation of the features of magnetite–hematite ores from the Mikhailovskoye deposit, a technological scheme of magnetoflotation beneficiation was proposed, which allows producing iron concentrates with 69% of iron content and less than 27% silicon dioxide for the production of pellets The technologies applicable to beneficiating iron ore fines include wet and dry gravity and magnetic separation, flotation, and roasting followed by magnetic separation A commercial flowsheet is expected to involve the implementation of several of these separation technologiesBeneficiation Strategies for Removal of Silica and Alumina from

In this paper, the mineral beneficiation process for hematite is studied, where the technique of screeningroastinggrindingmagnetic separationdewatering is adopted According to Fig 1, the raw ore is classified into particle ore that is 0–15 mm in size and lump ore larger than 15 mm in size during the screening unit processThe beneficiation of iron ore in the size range of 32 +02 mm is well established globally Dense medium separation (DMS) and gravity concentration are the beneficiation processes used Iron ore production in this size range is almost exclusively based on haematiteMaximizing haematite recovery within a fine and wide particle

The detection of the magnetic properties of haematite plays an important role in the adjustment of the beneficiation process of haematite and the improvement of metal recovery The existing methods for measuring the In this paper, a sample from Tangezagh iron mine was characterized by gravity and magnetic separation methods The mineralogical studies showed that hematite and goethite are the main ironbearing minerals with insignificant amounts of FeO The results indicated that spiral separation yields higher separation efficiency than A Beneficiation Study on a Low Grade Iron Ore by Gravity and

In Fig 3, the typical beneficiation of the oxide iron ores magnetite and haematite are shown Easiest to beneficiate are haematite ores (bottom part of the picture) In simplified terms, the process steps comprise “MineCrushScreenSell” and are also described as DSO process (DSO = highgrade direct shipping ore)Beneficiation of Iron Ores Iron ore is a mineral which is used after extraction and processing for the production of iron and steel The main ores of iron usually contain Fe2O3 (70 % iron, hematite) or Fe3O4 Beneficiation of Iron Ores IspatGuru

Most processes rely on density differences to separate light minerals from heavier ones, so the ore is crushed and ground to release the ore minerals from the gangue Magnetic techniques also are used The upgraded ore, or concentrate, is in the form of a very fine powder that is physically unsuitable for blast furnace useThe aim of this study was to evaluate the applicability of beneficiating a lowgrade, hematitemagnetite ore (assaying 1864% Fe) for subsequent utilization In this study, process mineralogy and beneficiation of the ore were carried out in the laboratory First, mineralogical investigation shows that the main metal minerals are hematiteBeneficiation of a lowgrade, hematitemagnetite ore in China

to legaojm/m account on The findings indicate that in case of hematite iron ore associated with goethite and limonite, it is difficult to achieve high grade of concentrate above 65% Fe It depends on the amount ofBeneficiation of hematite iron ore containing goethite impurity

beneficiation techniques including: • Scrubbing • Crushing • Gravity and magnetic separation • The JKTech DropWeight Test measures Selective flocculation • the apparent breakage function of the Flotation SCRUBBING Scrubbing is the process whereby clays, slimes and any potential oxidization present in or on the ore typically using waterIn this paper, an effective method was developed to remove phosphorus and upgrade iron from high phosphorus oolitic hematite ore by high temperature flash reduction—a wet magnetic separation process A thermodynamic analysis of iron and phosphorus mineral reactions and experiments with FeP separation process were Metals Free FullText Synchronous Upgrading Iron and

The beneficiation of iron ore in the size range of 32 +02 mm is well established globally Dense medium separation (DMS) and gravity concentration are the beneficiation processes used Iron ore production in this size range is almost exclusively based on haematiteThe detection of the magnetic properties of haematite plays an important role in the adjustment of the beneficiation process of haematite and the improvement of metal recovery The existing methods for measuring the Study of the Magnetic Properties of Haematite

The mineralogical studies showed that hematite and goethite are the main ironbearing minerals with insignificant amounts of FeO The results indicated that spiral separation yields higher separation efficiency than othersHematite ore from Kryvyi Rih iron ore basin (Ukraine) was ground to a particle size <007 Iron ore concentrates have been generated utilizing the conventional beneficiation process and also by the approach of reduction roastingmagnetic separation The Fe contents of the hematite and the synthesized magnetite concentrate were found Kinetics of hematite to magnetite transformation by gaseous reduction

Most processes rely on density differences to separate light minerals from heavier ones, so the ore is crushed and ground to release the ore minerals from the gangue Magnetic techniques also are used The upgraded ore, or concentrate, is in the form of a very fine powder that is physically unsuitable for blast furnace useThe aim of this study was to evaluate the applicability of beneficiating a lowgrade, hematitemagnetite ore (assaying 1864% Fe) for subsequent utilization In this study, process mineralogy and beneficiation of the ore were carried out in the laboratory First, mineralogical investigation shows that the main metal minerals are hematiteBeneficiation of a lowgrade, hematitemagnetite ore in China

Beneficiation of Iron Ores Iron ore is a mineral which is used after extraction and processing for the production of iron and steel The main ores of iron usually contain Fe2O3 (70 % iron, hematite) or Fe3O4 The findings indicate that in case of hematite iron ore associated with goethite and limonite, it is difficult to achieve high grade of concentrate above 65% Fe It depends on the amount ofBeneficiation of hematite iron ore containing goethite impurity

Refractory iron ore is often discarded as tailings This causes a great waste of iron resources In this paper, the flash roastingmagnetic separation process was designed by combining the magnetic separation process of magnetite and the process mineralogy of iron tailings The flash suspension roasting effects with 3–4 s to legaojm/m account on m/ hematite ore circuit · legaojm/m

A Jankovic, in Iron Ore, 2015 81 Introduction Hematite and magnetite are the most prominent iron ores Most of the highgrade hematite iron ores (direct shipping ore (DSO)) are subjected to simple dry processes of beneficiation to meet size requirementsIn this paper, an effective method was developed to remove phosphorus and upgrade iron from high phosphorus oolitic hematite ore by high temperature flash reduction—a wet magnetic separation process A thermodynamic analysis of iron and phosphorus mineral reactions and experiments with FeP separation process were Metals Free FullText Synchronous Upgrading Iron and

The narrowlevel selection of the ore beneficiation process can prevent the flotation process mentioned above easily The occurrence of chaos has improved the efficiency of mineral processing 3The process flow of stage grindingcoarse subdivisionmagneticheavyanion reverse flotation The characteristics of the process are:Overall Hematite beneficiation process 1Hematite ore crushing: in this stage there are also three steps, the hematite ore may go through primary crushing, secondary crushing and fine crushingHematite Separation Process