portland cement, binding material in the form of a finely ground powder, usually gray, that is manufactured by burning and grinding a mixture of limestone and Ordinary Portland cement, the most widely used standard variety, is made by grinding up limestone and then cooking it with sand and clay at high heat, which is produced by burning coal The process New approach suggests path to emissionsfree cement

Lime is produced from naturally occurring limestone by subjecting the limestone to a temperature in the range of 2200°F for The Portland clinker essentially consists of four minerals: two calcium silicates, alite (Ca3Si) and belite (Ca2Si), along with tricalcium aluminate (Ca3Al) and calcium aluminoferrite (Ca4AlFe) (Ca3Si), Ca2Si, Ca3Al, Ca4AlFe are abbreviations reflecting the stoichiometry of key elements) These main mineral phases are produced by heating at high temperature clays and limestone The major raw material for the clinkermaking is usually limestone mixed with a second material contCement clinker

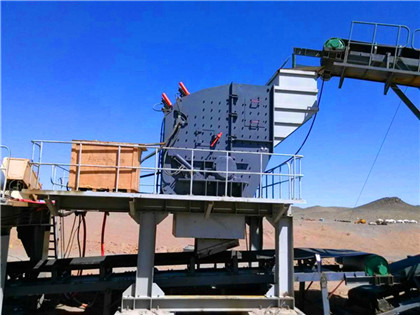

There are four stages in the manufacture of portland cement: (1) crushing and grinding the raw materials, (2) blending the materials in the correct proportions, (3) burning the prepared mix in a kiln, and (4) grinding the The limestone grinding process will start after the crushed limestone entering the mill 3Classification with a powder separator The limestone powder is classified by the powder separator, and the limestone powder Limestone Mill for Limestone Powder Grinding

The powdered limestone and water washed clay are sent to flow in the channels and transfer to grinding mills where they are completely mixed and the paste is formed, ie, known as slurry The grinding process can Lime Burning Chalk is a form of calcium carbonate which when burnt at about 900 degrees C becomes quicklime (calcium oxide) If water is added it becomes slaked lime (calcium hydroxide) Lime putty is made by adding Lime Burning Brockham History

Volume 0% To clean up after stump grinding, begin by removing chunks of wood, debris, and smaller chunks with a rake Next, dispose of the debris, and pave over the area It is important to properly clean up after stump Calcium oxide (also called quicklime, burnt lime, or unslaked lime) is formed by burning limestone Quicklime reacts with water, generating a great amount of heat We distinguish softburnt lime, mediumburnt lime, and hardburnt lime In the construction industry, quicklime is added to mortar It can also be used as a drying or neutralizingQuicklime preparation Gebr Pfeiffer

Ordinary Portland cement, the most widely used standard variety, is made by grinding up limestone and then cooking it with sand and clay at high heat, which is produced by burning coal The process Low temperature, inadequate calcination and serious lime burning can not meet the requirements; conversely, excessive ratio can easily cause nodulation Summary of Grinding Basic Knowledge ⅡWhat are the influencing factors of calcination of limestone?

Lime is produced from naturally occurring limestone by subjecting the limestone to a temperature in the range of 2200°F for sufficient time to drive off the carbon dioxide and produce the product Answer (1 of 7): Limestone is chemically calcium carbonate As Dolomits it is a mixture of magnesium and calcium carbonate Ket’s stick to limestone, calcium carbonate When heated it will decompose to form carbon dioxide and calcium oxide This is the basis of lime products such as lime mortar,What happens when limestone is heated? Quora

Lime burning produces quicklime/calcium oxide (CaO) and carbon dioxide (CO 2) which escapes into the environment This reaction takes places at temperatures above 700°C Quicklime is highly The major raw material for the clinkermaking is usually limestone mixed with a second material containing clay as a source of aluminosilicate An impure limestone containing clay or silicon dioxide (SiO 2) can be used Cement clinker

Volume 0% To clean up after stump grinding, begin by removing chunks of wood, debris, and smaller chunks with a rake Next, dispose of the debris, and pave over the area It is important to properly clean up after stump Burning Grinding Mixing of raw materials The raw materials such as limestone or chalk and shale or clay may be mixed either in dry condition or in wet condition The process is accordingly known as the dry process or Cement Manufacturing Process Civil Engineering Blog

Burning limestone, which is calcium carbonate, gives you quick lime, calcium oxide Mixed with water this produces slaked lime, calcium hydroxide When slaked lime or quick lime was added to the land it raised its pH and so improved its fertility Slaked lime was also used as lime putty for buildingHydraulic lime produced in powder form by burning high and low claysandy limestone and quenching by grinding or not grinding are called “Natural Hydraulic Lime” (NHL) Lime with suitable pozzolanic or hydraulic materials up to 20% by mass is called NHLP Organic additives are added to all HL and NHL typesTypes and Uses of Lime in Construction (Civil Engineering)

The methodology of this research work, are; 10g samples of clinker were collected on the apron conveyor chute with liter weights, (table 21), the weighted samples (10g) of clinker were milled andlimestone burning, the following pollution preven tion and control techniques, in addition to proper smoothing of kiln operations, 2 are recommended: 2 Smoothing of kiln operations refers to maintaining the kiln in consistently optimum operating conditions • Capturing kiln and cooler dusts using filters and recyclingFinal Cement and Lime Manufacturing International

Lime production comprises various processes: Quarrying of raw limestone, crushing and sizing Calcining (burning) limestone in a kiln or calciner Processing the lime further by hydrating, mixing with water if necessary (Not all lime is hydrated or “slaked” much is sold as quicklime, or unhydrated calcium oxide)Calcium oxide (also called quicklime, burnt lime, or unslaked lime) is formed by burning limestone Quicklime reacts with water, generating a great amount of heat We distinguish softburnt lime, mediumburnt lime, and hardburnt lime In the construction industry, quicklime is added to mortar It can also be used as a drying or neutralizingQuicklime preparation Gebr Pfeiffer

Lime is produced from naturally occurring limestone by subjecting the limestone to a temperature in the range of 2200°F for sufficient time to drive off the carbon dioxide and produce the product Low temperature, inadequate calcination and serious lime burning can not meet the requirements; conversely, excessive ratio can easily cause nodulation Summary of Grinding Basic Knowledge ⅡWhat are the influencing factors of calcination of limestone?

Threering mediumspeed micro mill Get Latest Price The threering mediumspeed micro milling machine is named because of its design with three grinding rings It is suitable for making fine and ultrafine powder The particle size of limestone powder can be adjusted arbitrarily between 3252500 mesh, and the output can reach Limestone is chemically calcium carbonate When limestone is heated strongly, the calcium carbonate it contains absorbs heat (endothermic) and decomposes to form calcium oxide (also known as quicklime or lime) This is also a link in the limestone cycle Here are other reactions The reaction of calcium oxide with water produces calcium hydroxideWhat happens when limestone is heated? Quora

Technical Association of the Pulp & Paper Industry IncUploaded on Nov 27, 2010 This is from the Edwardian Farm series how to make 10 tons of lime mortar in a massive kiln using layers of limestone and coal burnt for days! Lime Works us Phone: 2455366706Burning Lime, The Traditional Way LimeWorksus

Volume 0% To clean up after stump grinding, begin by removing chunks of wood, debris, and smaller chunks with a rake Next, dispose of the debris, and pave over the area It is important to properly clean up after stump Burning Grinding Mixing of raw materials The raw materials such as limestone or chalk and shale or clay may be mixed either in dry condition or in wet condition The process is accordingly known as the dry process or Cement Manufacturing Process Civil Engineering Blog

Burning limestone, which is calcium carbonate, gives you quick lime, calcium oxide Mixed with water this produces slaked lime, calcium hydroxide When slaked lime or quick lime was added to the land it raised its pH and so improved its fertility Slaked lime was also used as lime putty for buildingHydraulic lime produced in powder form by burning high and low claysandy limestone and quenching by grinding or not grinding are called “Natural Hydraulic Lime” (NHL) Lime with suitable pozzolanic or hydraulic materials up to 20% by mass is called NHLP Organic additives are added to all HL and NHL typesTypes and Uses of Lime in Construction (Civil Engineering)

Lime production comprises various processes: Quarrying of raw limestone, crushing and sizing Calcining (burning) limestone in a kiln or calciner Processing the lime further by hydrating, mixing with water if necessary (Not all lime is hydrated or “slaked” much is sold as quicklime, or unhydrated calcium oxide)Factors affecting Properties of Lime Mortar 1 The free calcium amount present in the lime mortar 2 The free lime content and porosity are directly proportional 3 The fat lime or nonhydraulic lime does not set under water, it sets with time 4 The hydraulic lime sets after the addition of waterBuilding Lime Properties, Advantages and Uses of Lime in

The lime kiln burner needs to be flexible and able to safely and efficiently burn several different types of fuel Suitable solution for both old and new mills “We have shown during the last decade that wood powder firing has become a fully commercial, proven and most importantly safe solution for lime kilns