Influences of different grinding aids on dry fine grinding of calcite using a laboratorytype ball mill were investigated Tested grinding aids had affected the flowability and overlapped with grinding performance results The positive effects of grinding aids One of the applications used in the dry fine grinding of calcite is the ball mill technology with the use of cylpebs Therefore, in this experimental study, laboratory Analysis of grinding aid performance effects on dry fine milling of

The results showed that modified calcite powder (BMC3) with a coating rate of 105%, a mean particle size of 1018 μm, oil In addition, the capacity of the conventional ball mill for the fabrication of nanosized products should be significantly reduced When the mill capacity is reduced by 75% (5 Grinding of Calcite to NanoSize: Effect of Mill Capacity and

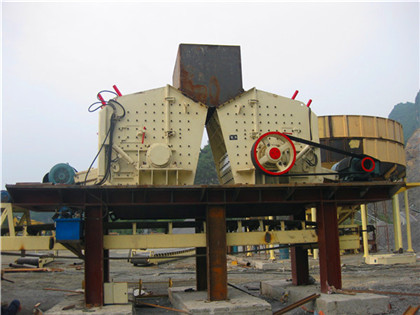

calcite grinding mill is a new type of ultra fine grinding mill independently developed by CLIRIK, specialized in the grinding production of over a hundred kinds of ores such as to legaojm/m account on m/ calcite grinding mobile · legaojm/m

calcite ball mill is one kind of calcite grinding mill used in calcite powder making, finished powder fineness: 50 mesh to 1000 mesh Shanghai clirik machinery is a professional Calcite or ground calcium carbonate (GCC), which has a Mohs hardness value of 3, a refractive index value of about 170, and a density of nearly 27 g/cm 3, is a Minerals Free FullText Comparison of Particle Shape, Surface

There are several types of calcite grinding mills available, including ball mills, raymond mills, vertical mills, and ultrafine mills Ball mills are the most A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paintsBall mills rotate around a horizontal axis, partially filled with the material to Ball mill

Influences of different grinding aids on dry fine grinding of calcite using a laboratorytype ball mill were investigated Tested grinding aids had affected the flowability and overlapped with grinding performance results The positive effects of grinding aids on color properties were demonstratedAs a result of this study, optimum grinding test conditions determined to be 70% of Nc, J=035 for ball filling ratio, 40 mm (10%), 32 mm (10%), 20 mm (40%), 12 mm (40%) for ball sizeInfluences of operating parameters on dry ball mill performance

Understanding the energysize reduction relationship is vital to grinding process; therefore, this paper aims to show the energysize reduction of magnetitecalcite binary mixture in a laboratory wet conical ball mill Single magnetite, single calcite, and blended magnetitecalcite mixture at three weight ratios in four particle sizes were In this study, calcite (CaCO 3) samples provided by Micron’S Company (Niğde, Turkey) were used in the grinding tests, and their density was determined by using a helium pycnometer and found to be 270 g/cm 3 The chemical composition of the sample from the analysis performed using Xray fluorescence is given in Table 1The Influence of Stirred Mill Orientation on Calcite Grinding

In an experiment using a stirred ball mill and grinding aids (Paramasivam and Vedaraman, 1992, Effect of grinding aids on the kinetics of fine grinding energy consumed of calcite powders by a stirred ball mill Adv Powder Technol, 20 (2009), pp 350354 Article Download PDF View Record in Scopus Google Scholar Fuerstenau, Planetary ball milling, which is one of the most frequently used labscale milling tools, has been applied to increase the grinding efficiency of talc The collision impact and friction between powder samples and balls in a rotating jar grind the microscale talc into submicroscale particlesMinerals Free FullText Effects of Ball Size on the Grinding

This paper presents the kinetics study of dry ball milling of calcite and barite minerals The experimental mill used was a laboratory size of 209 mm diameter, 175 mm length, providing a totalIn addition, the capacity of the conventional ball mill for the fabrication of nanosized products should be significantly reduced When the mill capacity is reduced by 75% (5 tph) and grinded with Cylpebs, the fineness (d 90) of the product reaches 1300 nanometers Key words: Ball Mill, Ball, Calcite, Cylpebs, Nano Grinding 1 IntroductionGrinding of Calcite to NanoSize: Effect of Mill Capacity and

to legaojm/m account on Calcite is an ideal mineral raw material for the production of calcium carbonate, with characteristics such as large resource reserves, high grade, and good whiteness The calcite grinding mill machine is currently the main equipment for the production of heavy calcium carbonate The key to the cost of a calcite grinding mill machine depends on How Much Is A Calcite Grinding Mill? Capacity And fineness Are

The ball mill Ball milling is a mechanical technique widely used to grind powders into ne particles and blend materials18 Being an environmentallyfriendly, costeffective technique, it has found wide application in industry all over the world Since this minireview mainly focuses on the conditions applied for the prepSince the particle size, shape, specific surface area, and purity of the ground calcium carbonate (GCC) decide its usability in the paper, paint, and plastic industries, the effect of grinding is important However, the effect of stirred and ball mill grinding on the particle shape of GCC by dynamic image analysis (DIA) is still lacking in Minerals Free FullText Comparison of Particle Shape, Surface

After calcite is ground by an industrial grinding mill, calcite powder can be obtained Calcite powder of different fineness is widely used in many fields such as papermaking, medicine, chemical industry, agriculture and so on High grinding efficiency: save 20~30% power consumption compared with the ball mill 2 Strong There are several types of calcite grinding mills available, including ball mills, raymond mills, vertical mills, and ultrafine mills Ball mills are the most commonly used typecalcite grinding mill

In this paper, two minerals, magnetitecalcite, were used to feed in the conical ball mill for wet grinding, and the energy consumption for grinding single mineral and for the mixture were measured In addition, Rosin–RammlerBenne model was used to predict the particle size distribution of single and mixed ground productIn an experiment using a stirred ball mill and grinding aids (Paramasivam and Vedaraman, 1992, Effect of grinding aids on the kinetics of fine grinding energy consumed of calcite powders by a stirred ball mill Adv Powder Technol, 20 (2009), pp 350354 Article Download PDF View Record in Scopus Google Scholar Fuerstenau, Effect of grinding aids on the grinding energy consumed during grinding

In this study, calcite (CaCO 3) samples provided by Micron’S Company (Niğde, Turkey) were used in the grinding tests, and their density was determined by using a helium pycnometer and found to be 270 g/cm 3 The chemical composition of the sample from the analysis performed using Xray fluorescence is given in Table 1Since the particle size, shape, specific surface area, and purity of the ground calcium carbonate (GCC) decide its usability in the paper, paint, and plastic industries, the effect of grinding is important However, the effect of stirred and ball mill grinding on the particle shape of GCC by dynamic image analysis (DIA) is still lacking in Minerals Free FullText Comparison of Particle Shape, Surface

This paper presents the kinetics study of dry ball milling of calcite and barite minerals The experimental mill used was a laboratory size of 209 mm diameter, 175 mm length, providing a total% 98824 0489 0388 0100 0065 0052 0022 0025 0020 0015 Grinding tests were carried out in a dry stirred ball mill both vertical and horizontal orientations with varyingThe Effect of Stirred Mill Orientation on Calcite Grinding

This study investigated ultrafine coal grinding performance of four low to moderatecost grinding media in a laboratory stirred mill Kinetic grinding tests showed that silica beads generated the finest product size with a P 80 of 59 μm from a feed size of 244 μm while having a specific energy (SE) input of 309 kWh/ton Nonetheless, the least The ball mill Ball milling is a mechanical technique widely used to grind powders into ne particles and blend materials18 Being an environmentallyfriendly, costeffective technique, it has found wide application in industry all over the world Since this minireview mainly focuses on the conditions applied for the prepBall milling: a green technology for the preparation and

In addition, the capacity of the conventional ball mill for the fabrication of nanosized products should be significantly reduced When the mill capacity is reduced by 75% (5 tph) and grinded with Cylpebs, the fineness (d 90) of the product reaches 1300 nanometers Key words: Ball Mill, Ball, Calcite, Cylpebs, Nano Grinding 1 IntroductionCalcite is an ideal mineral raw material for the production of calcium carbonate, with characteristics such as large resource reserves, high grade, and good whiteness The calcite grinding mill machine is currently the main equipment for the production of heavy calcium carbonate The key to the cost of a calcite grinding mill machine depends on How Much Is A Calcite Grinding Mill? Capacity And fineness Are

to legaojm/m account on mill speed (% of Nc), ball filling ratio (J), ball size distribution (%), powder filling ratio (fc), grinding aid dosage (g/Mg) and grinding time (min) on the dry fine grinding of calcite using a laboratory batch scale conventional ball mill The evaluation of the results of grinding tests was performed based on the product particle size (d 50Influences of operating parameters on dry ball mill

After calcite is ground by an industrial grinding mill, calcite powder can be obtained Calcite powder of different fineness is widely used in many fields such as papermaking, medicine, chemical industry, agriculture and so on High grinding efficiency: save 20~30% power consumption compared with the ball mill 2 Strong Calcite Gypsum Activated Carbon Bentonite Clay Charcoal Powder Grinding Mill Machine Raymond Vertical Mill,Find Complete Details about Calcite Gypsum Activated Carbon Bentonite Clay Charcoal Powder Grinding Mill Machine Raymond Vertical Mill,Calcite Gypsum Activated Carbon Bentonite Clay Charcoal Powder Grinding Mill Machine Calcite Gypsum Activated Carbon Bentonite Clay Charcoal Powder Grinding